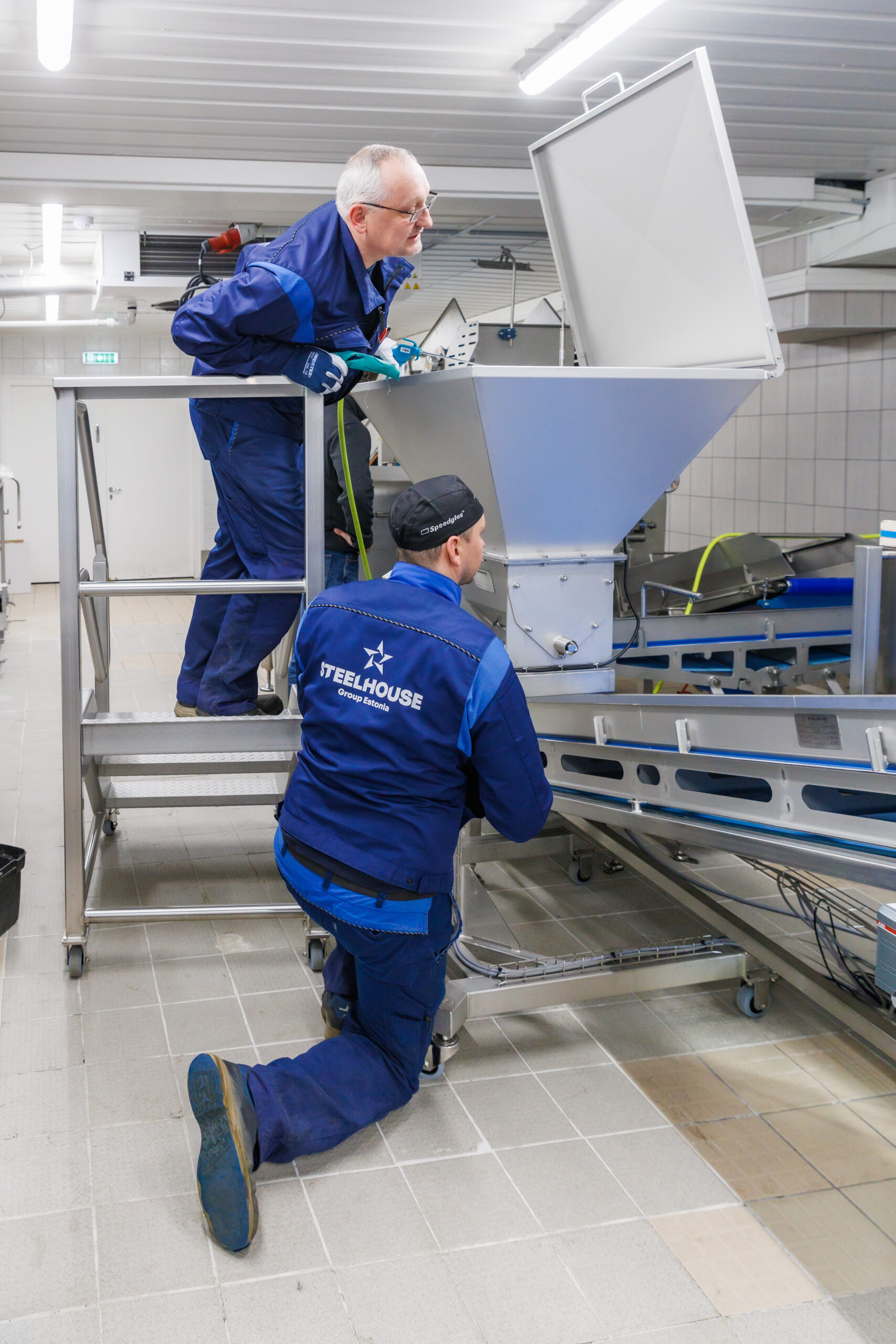

In cooperation with automation specialists, we offer our clients solutions for automating manufacturing – from planning to robotic systems and all associated hardware components.

Automation helps reduce labour costs while improving manufacturing efficiency and quality.

Send us a requestPlanning and robotic systems

Planning helps to optimise the movement of products from one point to another.

We offer palletising, packaging, and quality control with 3D cameras using robots. These systems are simple and quick to install and require no specialised knowledge from the operator. Palletising and packaging are the most commonly used robotic solutions and are suitable for nearly all industrial clients.

Robots can be equipped with up to five different tools simultaneously, allowing for a more dynamic workflow. It is also common for two or more robots to work together in our systems, using fixed systems when necessary to continue operations.

For clients seeking a solution where humans and robots can work together, collaborative robots are the most suitable choice.

Automation

We offer PLC programming for industrial equipment and lines – either from start to finish or help complete unfinished programmes. Our range includes robots from Fanuc, UR and ABB, and PLCs from Siemens.

IoT and IO-Link (monitoring/SCADA)

We offer widely recognised SCADA systems as well as custom-developed software solutions. This software enables the integration of various machines and lines, allows for real-time monitoring, and supports the creation of various data visualisations. We provide both autonomous systems hosted on the client’s own server and dynamic systems managed by us.

AI and IT

The application of artificial intelligence (AI) in industry helps companies perform their work more effectively, plan more efficiently, and operate equipment more efficiently. AI makes it possible to reduce resource use, process vast amounts of data, and in certain cases, outperform human decision-making. Replacing routine and time-consuming manual labour with automation systems plays a key role in improving company efficiency. AI can boost industrial productivity by enabling the use of robots in manufacturing, optimising sales channels, planning smart factory maintenance in a timely manner, and predicting failures.

In cooperation with our automation specialists, we design industry-leading deep learning software platforms. We integrate equipment into existing warehouse systems via XML or another data format, enabling the machines to independently read work orders and stock levels, and to make decisions or initiate production accordingly.

Testing

Optimisation through testing

Each new system is assigned a specific number of test runs, all of which must be successfully completed. We also carry out FAT tests to ensure, together with the client, readiness before delivering the equipment to their production facility.

Training

An operator manual and a commissioning manual are prepared for each piece of equipment. Accordingly, operator training is conducted at the client’s manufacturing facility, focusing on the proper use of the equipment and correct maintenance procedures.

KONTAKT