Metal laser cutting is done with a sheet laser and tube laser, according to the customer’s needs.

Our main customers for laser cutting are metalworking industries that require mass production or special solutions.

We also offer customised solutions made from non-ferrous metal for designers and interior architects, and provide them with advice and recommendations.

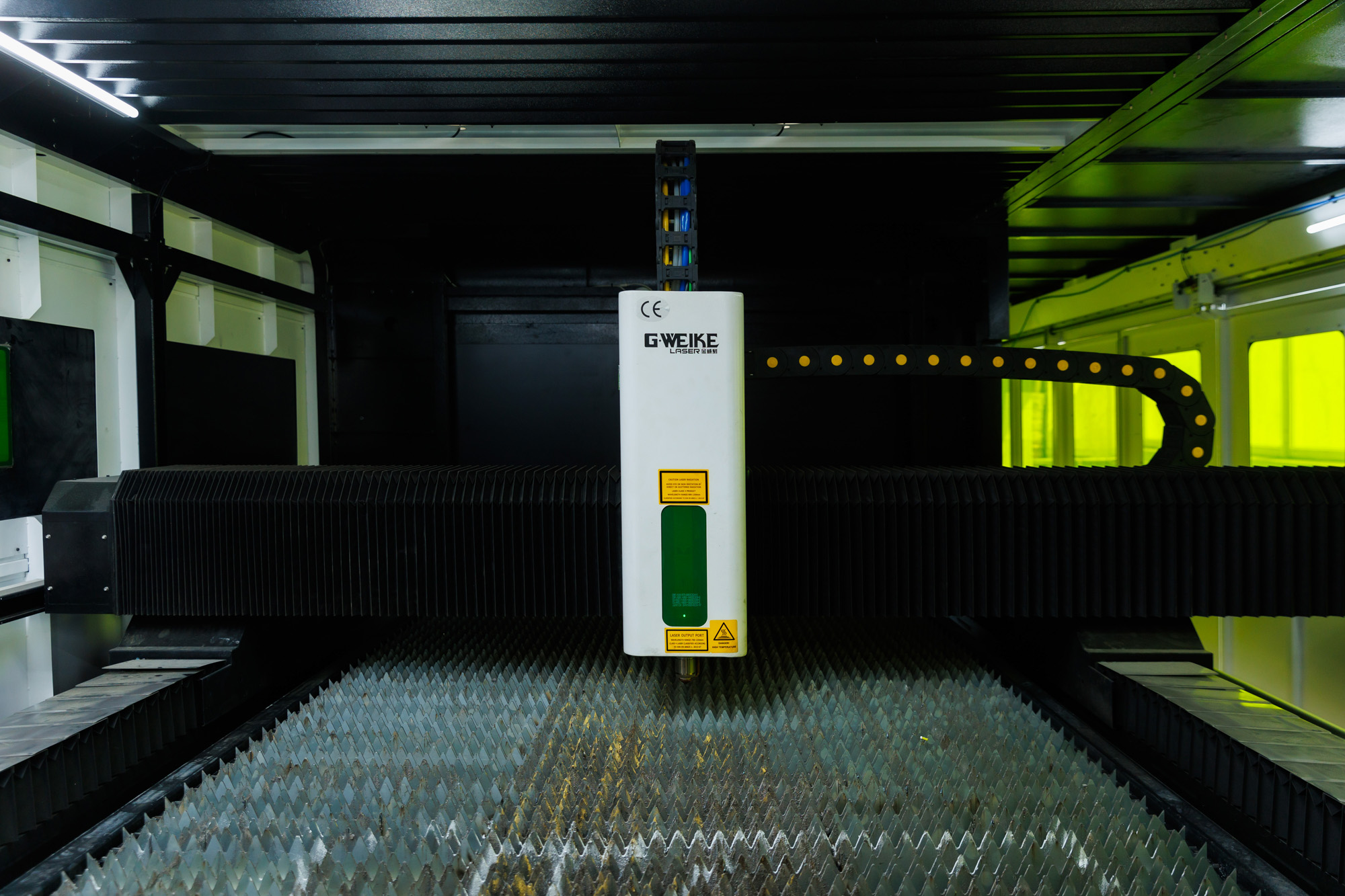

Send us a requestSHEET METAL LASER CUTTER

Sheet laser

We cut out details and blanks from sheet metal according to the customer’s drawings or sketches. Laser cutting using a sheet laser makes it possible to cut parts very quickly and accurately. This saves time, as the parts do not have to be processed manually. The laser cuts out holes, which are immediately ready for use, for example, for threading.

We usually stock sheet material with a 2B surface finish, which can be customised with a brushed surface and/or film coating upon the customer’s request.

Materials cut

Stainless steel, aluminium, brass and copper

Sheet laser capacity

Material thickness: 0.5 to 15 mm

Max sheet size: 1500 × 3000 mm

Stainless steel: up to 15 mm

Brass: up to 10 mm

Copper: up to 8 mm

Aluminium: up to 15 mm

TUBE LASER CUTTER

Tube laser

The tube laser cutter is able to cut parts from different pipe profiles. Pipes can be both round and square, with an oval or rectangular cross-section. If the diagonals are within the limits suitable for the laser, the profile of the pipe does not set limits for laser cutting. The advantage of cutting with a tube laser is accuracy. Since the parts are not processed manually, the work process is significantly faster and all parts are always identical.

Materials cut

Stainless steel, brass, copper, aluminium and steel.

Tube laser capacity

Outer diameter or diagonal of the pipe: 10 mm to 220 mm

Max pipe length: 6 m

Tube profiles: round, square, rectangular hollow section, u-profile

CONTACT US