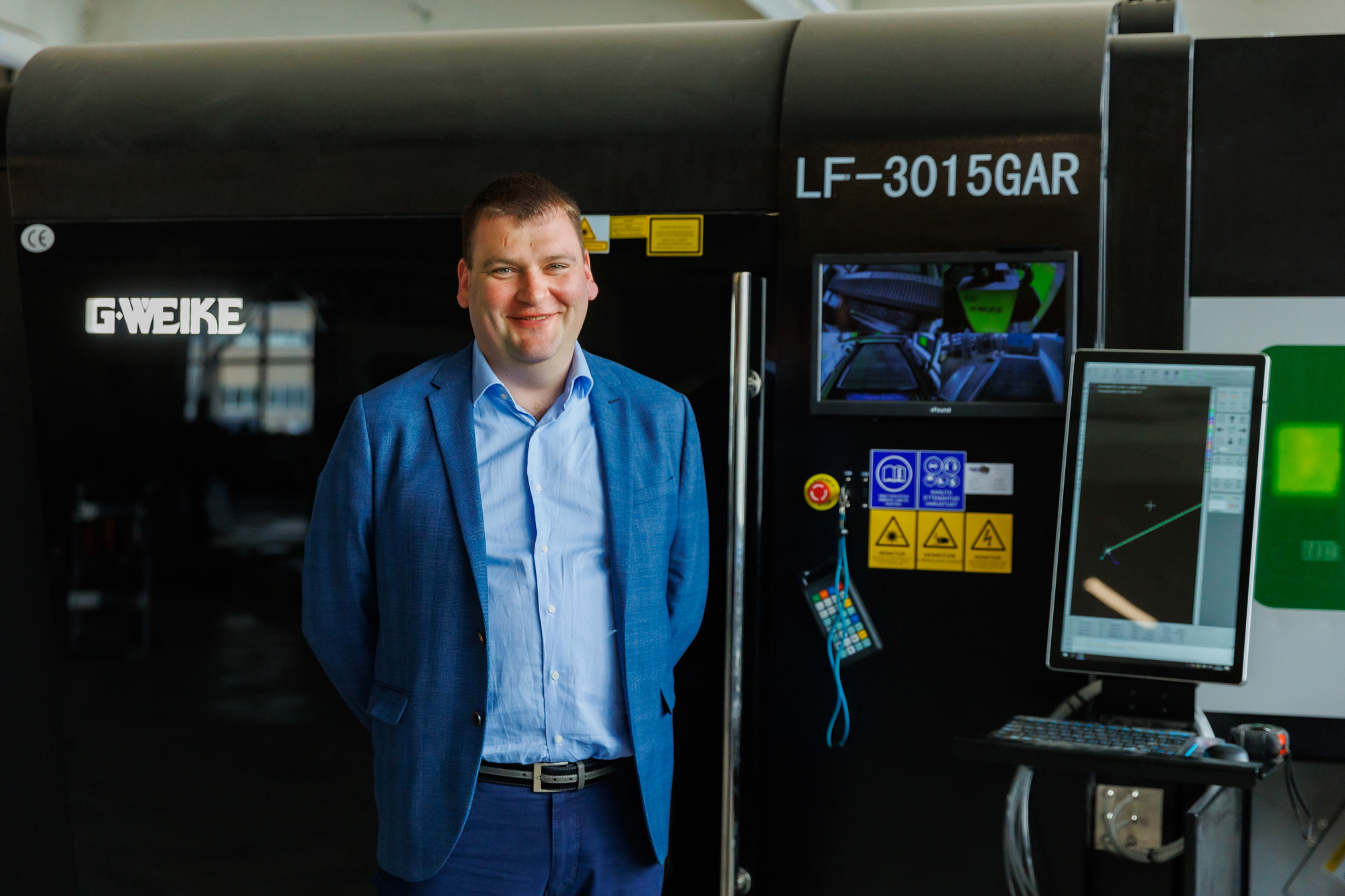

CEO in overalls:

I like to do things that others can’t wrap their heads around

Every day, Valmar Kask dons his workwear to work in the production facilities of Steelhouse Group Estonia, where special orders made of non-ferrous metals are fulfilled.

Steelhouse Group specialises in developing and manufacturing a wide range of metal products and solutions. The company’s activities range from laser cutting and finishing of metal products to the design and installation of highly complex structures. Using stainless steel, aluminium, copper, and brass, Steelhouse is able to provide solutions for a wide range of industries, including demanding ones such as the food industry and medical industry.

No mass production

The company appreciates a project-based approach, built on flexibility and customer-centric solutions. This approach ensures that each order receives the necessary commitment and production is customised to meet the customer’s specific needs and requirements. As each project is unique, resources are adapted to the scale and complexity of the job. Project-based design encompasses all stages, from designing and planning to production and installation.

Born at the workplace, not in a quiet office

The company was founded by a CEO with 15 years of experience working across the Gulf of Finland. He began his career as a painter and grinder and gradually became a leading specialist in non-ferrous metals. ‘At one point, I just got bored of living and working abroad and told them I was coming back home. Tapio Hyytiäinen, the owner of Finnish Steelhouse, had the idea to establish a separate company with the same name in Estonia. In 2021, we began with a few employees in a 1,000 square metre building. Today, we already have three buildings and production on more than 5,000 square metres,’ Kask recalls.

Steelhouse’s growth story illustrates how a small Estonian company can rapidly become a successful player in international markets. Production from the unit in Vinni Industrial Park reaches all seven continents. According to Kase, their success is attributed to their staff’s technical know-how and extreme flexibility, enabling quick response to specific customer needs. ‘We only outsource tube bending and CNC machining

Everything else, from sanding and passivation to installation, we do ourselves. Put simply, we manufacture products ourselves, install them, and get them working – it’s the only way we can ensure continuous quality control at every stage,” says the company’s CEO.

Intellectual and manual labour

Unlike many other companies, where management can be far removed from production, Steelhouse’s management is intimately familiar with non-ferrous metals due to personal experience. The close link between management and production creates a strong internal culture in the company, where employees feel that their work is important and appreciated, and the company values smart and committed people over machines.

‘Here, people are not just operators on the production line but an integral part of the company’s strategic plan. That’s why it’s important for them to feel motivated and happy with their working conditions. If those two things are not in place, people won’t bother to grow with the company,’ Kask is convinced.

This experience is also reflected in the pricing of projects, which is transparent and specific – the offers don’t include anything excessive.

‘Each quotation is based on accurate calculations, considering all factors, including material costs, labour, technologies used, and the project’s complexity. Steelhouse never sets prices that can be discounted by 50% in a week. Clients always get a clear overview of what their investment covers, with no hidden costs or unexpected additional charges. If the offer is not suitable, someone else will do the job. We will never take on a project where the cost cannot guarantee quality. ‘Our prices are fair and accurate. It is not uncommon for a customer to return with the same order after evaluating other offers on the market,’ says the company’s CEO.

Steelhouse Group is not planning to remain at its current capacity but aims to expand production to meet increasing demand. But the goal is not just to grow bigger but to grow better.